This deflection of fixture is caused because of forces of cutting clamping of the workpiece or clamping to the machine table. The 0 corner is to be painted Yellow.

Designing Jigs And Fixtures Design Guide Vention

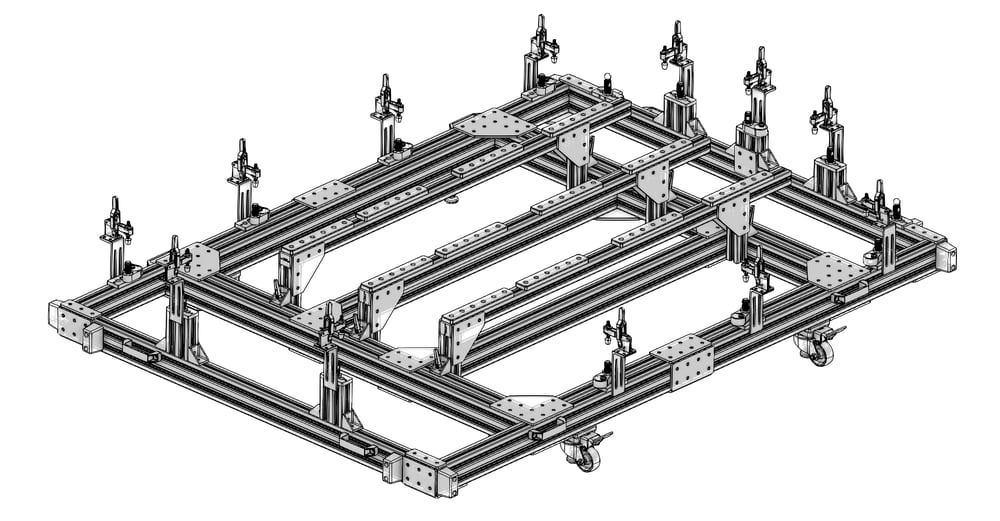

Checking Fixtures must be design to allow measurements with horizontal arm CMM with the above working envelope.

. A check fixture differs from a jig in that the jig is essentially a holding device to hold the piece part while work or inspection is performed. Using this a formal generalization of the concepts and methodologies of fixture design for Tinker will be developed. Benefit Fixture Required Economics MFG316 Chapter 6 Machine considerations.

Microsoft PowerPoint - 316CHAP6PPT Author. At first you were too busy getting your new life in order then you were worried about how you would all. 511 All check Fixtures are to be quoted as design and build.

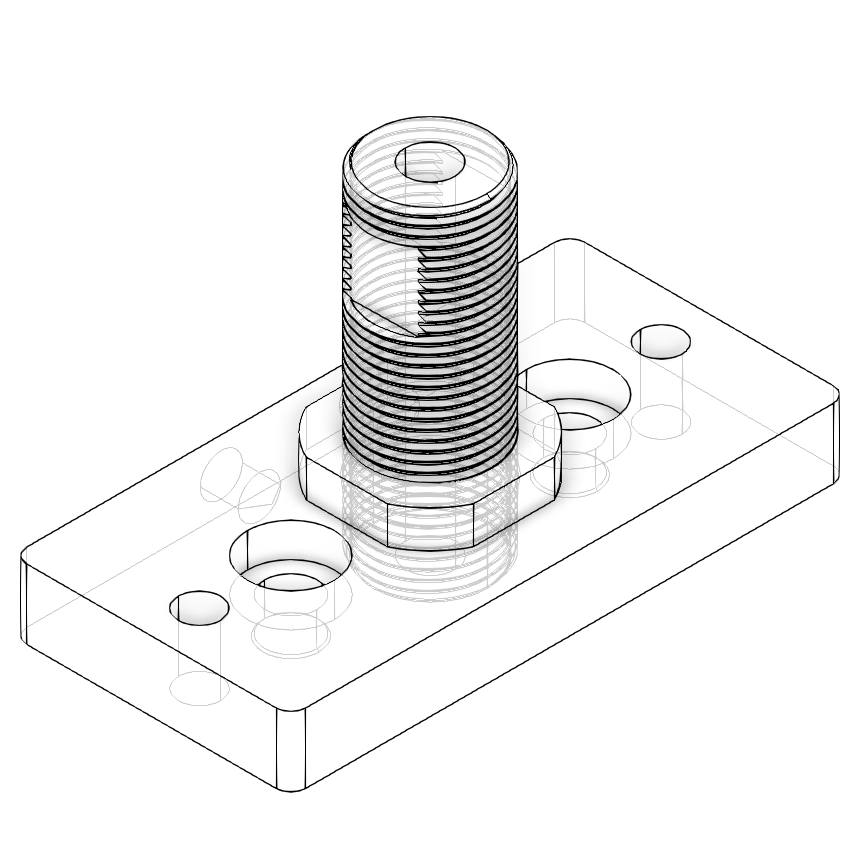

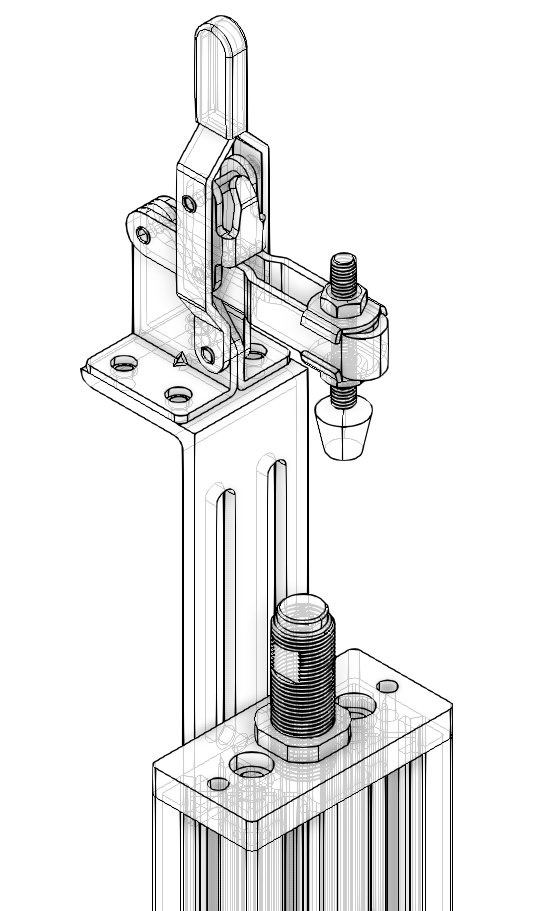

Identify material being used in stock list by detail. 42 DESIGN OF FIXTURES 421 Design Consideration in Fixtures a The main frame of fixture must be strong enough so that deflection of the fixture is as minimum as possible. Fig 4Basic design modifications on a fixture k.

Checking Fixtures must be design to allow measurements with horizontal arm CMM with the above working envelope. Up to 24 cash back Checking fixture design guidelines. Design of fixture checking including Position of hole and slot.

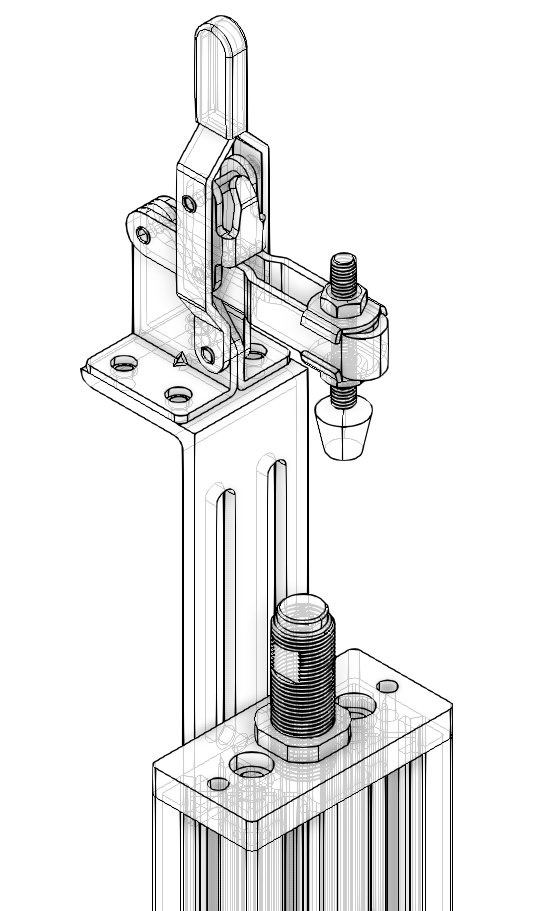

Currently we have 12 members on our design department2 of them are senior engineers who are experienced in checking fixture industries for more than 8 years. They are the most common type of fixture because their versatility makes them adaptable to a. Always aim at having a fixed rigid part of the fixture element to take up the cutting forces.

513 All quotes are to include. A minimum of 4 Jig Feet 380mm tall are required for all fixtures on aluminum plate. 43 part alignment on the checking fixture 12 44 part fixation means 13 45 types of checking systems for the dimensions to be checked 15 46 manufacturing materials 19 47 manufacturing tolerances 20 48 general identification.

4 of them are engineers with the related working experiences for minimum 5 years. Fixture Design Hold Locate Support MFG316 Chapter 6 General Considerations Cost vs. The main frame of the fixture should have.

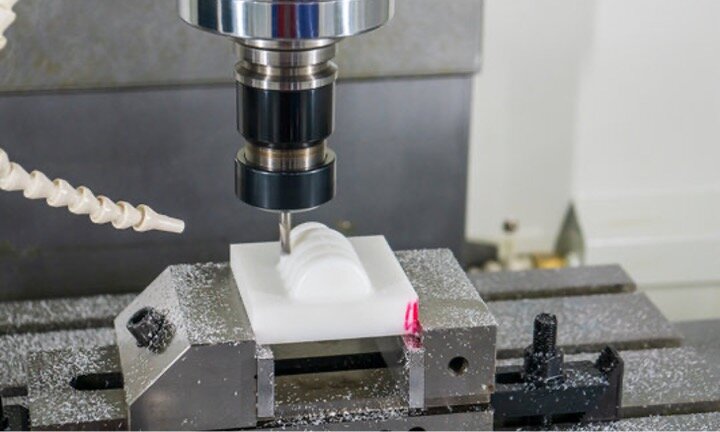

512 All quotes are to follow BAE. Fixture Design process Add cutters Check clearances Final drawings. A checking fixture is a quality assurance tool used in industries to check for the quality of components with complex shapes.

The maximum distance between two feet may not exceed 500mm see figure 25a. There are also 4 designers more than 3 years experiences. If the checking fixture were to exceed the CMM table size additional feet will be needed to sit level.

Test Fixture Wiring There are three major methods of establishing contact between the product printed circuit board being tested using a probe based test fixture commonly called bead-of-nails fixture. This document is intended as a guideline to make fixture sources aware of the build requirements and buyoff criteria that will provide the basis for fixture approval and invoice payment. They arent used in making components but to accept or reject already made components according to the dimensional accuracy.

To check and align mating parts due to automatic accurate positioning. Getting away occasionally can be healthy for both you and your little one. The design must possess enough rigidity and robustness to prevent vibration else it may lead.

114 Fixture Design Fundamentals. 80-ENG-D-413 Checking Fixture Gauge Standard 0-07Jul2020. The gage base is to have a 0 corner that designates two adjacent base edges as the master corner.

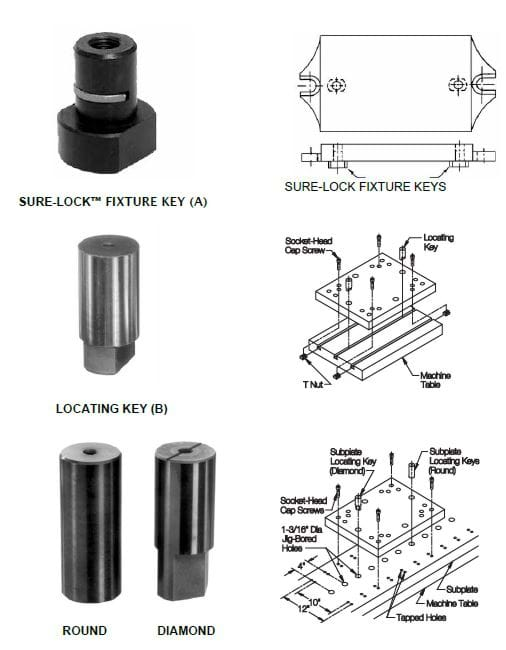

Standards unless otherwise requested. One should try to maintain at least one datum surface and have basic design modifications on a fixture. 14 Bathroom Design Guidelines Illustrated 2 Kitchen And Bath Design Bathroom Plan Design Guidelines A check fixture takes just a few moments to use see Figure 1.

Fixture Design Fundamentals of Tool Design Study Guide DV07PUB3 - 2 - Fixture types fall generally into five groups. In addition to these requirements a fixture design should have desirable characteristics such as quick loading and unloading minimum number of components accessibility design for multiple cutting operations portability low cost etc. Plate Fixtures Plate fixtures are constructed from a plate with a variety of locators supports and clamps.

Specific constraints for each shop will again be identified. These methods include long-wire short-wire and wireless fixtures. Checking fixtures and CMM holding fixtures are tools that dimensionally qualify detail parts or assemblies and audit manufacturing process variations.

You havent vacationed since your baby was born. Success depends on details. It is a work holding device that holds supports and locates the work-piece for a specific operation but does not guide the cutting tool.

Take note of the following guidelines. Identify net areas of fixture with cross-hatching on the design. Any deviation to BAE.

Checking Fixtures should be design to not exceed the CMM table size shown in 505. Manufacturers seek the help in checking fixtures to inspect the dimensional accuracy of their products. Hence a step-by-step procedure for jig and fixture design will be developed.

If weight exceeds 22 pounds 10 kg checking fixture lift areas will be called out labeled and shown in design for both Hilo and crane. Definition of Fixture. Type of fixture required attribute variable etc.

But how can you manage a holiday with a baby and all her gear in tow. The check fixture is a form of gage. Phase I 2 actual practical development at Tinker will be drawn.

A designer should have a good common sense in observing the direction of cutting forces too so as to decide the right type of location butting and clamping of the component. And must be etched or steel stamped on checking fixture. General Measurement Device and Calibration Topics.

Practical Aspect On Fixture Design Calculation

Designing Jigs And Fixtures Design Guide Vention

Designing Jigs And Fixtures Design Guide Vention

Principles Of Location In Jig Fixture Design Carr Lane

Design Principles Of Jigs And Fixtures Prescient Technologies

14 Bathroom Design Guidelines Illustrated 2 Kitchen And Bath Design Bathroom Plan Design Guidelines

What Is Jig Fixture Design Carr Lane Mfg Co

Design Principles Of Jigs And Fixtures Prescient Technologies

0 comments

Post a Comment